Magnesium Stearate

50.00 INR/Kilograms

Product Details:

- Refractive Rate 1.45

- Structural Formula Mg(CHCOO)

- HS Code 29157090

- Boiling point Not applicable (decomposes on heating)

- Taste Other

- Form Powder

- Smell Other

- Click to view more

X

Magnesium Stearate Price And Quantity

- 20 Kilograms

- 50.00 INR/Kilograms

Magnesium Stearate Product Specifications

- Magnesium stearate

- lubricant, glidant, cosmetic thickener

- Synthesized from stearic acid and magnesium salts

- Magnesium Stearate

- 6.58.5 (neutral to slightly basic in aqueous dispersion)

- 8890C (technical grade); pure form ~130140C

- 1.03 g/cm Gram per cubic centimeter(g/cm3)

- Room Temperature

- Insoluble in water and alcohol; slightly soluble in benzene and ether

- Typically 90%

- Industrial Grade

- Inorganic Chemicals

- Magnesium octadecanoate, stearic acid magnesium salt

- Mg(CHCOO)

- 1.45

- Other

- 29157090

- Not applicable (decomposes on heating)

- Industrial, Lubricants

- Powder

- Other

- 209-150-3

- 591.24 g/mol Grams (g)

- 557-04-0

- Complies with Industrial grade

- Mg(CHO)

Magnesium Stearate Trade Information

- Cash Advance (CA), Cash in Advance (CID)

- 500 Kilograms Per Day

- 5 Days

- Yes

- Free samples are available

- 25 Kg PP Laminated woven Bag

- All India

- An ISO 9001:2015 Certified Company

Product Description

Magnesium stearate is the chemical compound with the formula Mg(C18H35O2)2. It is a soap, consisting of salt containing two equivalents of stearate (the anion of stearic acid) and one magnesium cation (Mg2+). Magnesium stearate is a white, water-insoluble powder. Its applications exploit its softness, insolubility in many solvents, and low toxicity. It is used as a release agent and as a component or lubricant in the production of pharmaceuticals and cosmetics.

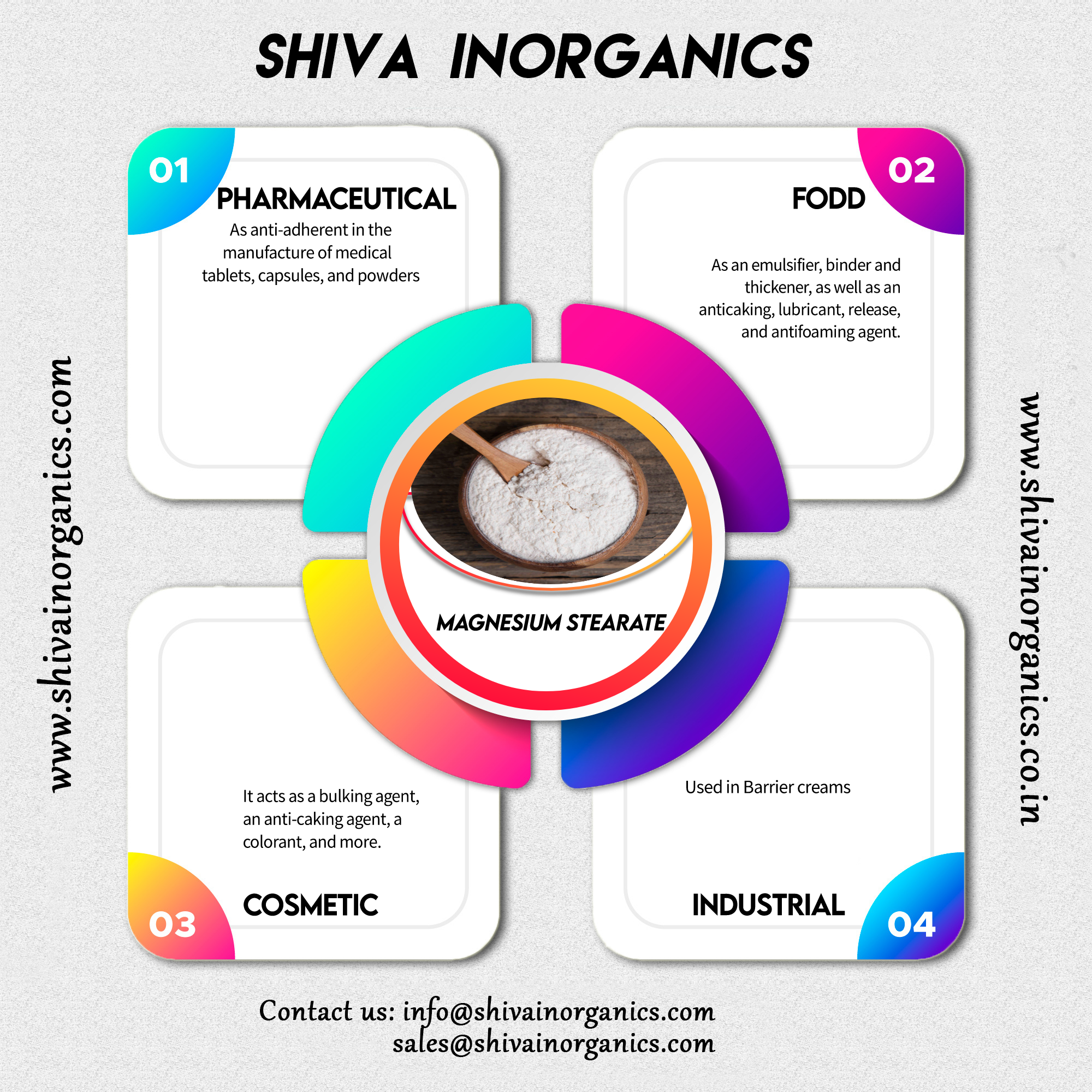

Diverse Pharmaceutical and Cosmetic Applications

Magnesium Stearate is highly regarded in pharmaceuticals and cosmetics for its lubricating, anti-adherent, and thickening properties. It acts as an essential excipient in tablet and capsule formulations, ensuring smooth processing and consistent quality. In cosmetics, it imparts a desirable texture, improves spreadability, and stabilizes product formulations, making it valuable for manufacturers seeking dependable performance.

Industrial Lubricant and Additive Qualities

With its unique chemical profile and low solubility, Magnesium Stearate serves as an effective industrial lubricant and glidant. Commonly added to inorganics and polymers, it enhances material flow and reduces friction during manufacturing. Its compatibility with various materials and neutral pH make it an important choice for coatings and processed goods.

Quality and Compliance Specifications

Our Magnesium Stearate meets strict industrial standards, with a purity of no less than 90% and compliance with industrial grade specifications. The product is distributed as a white powder, remaining stable at room temperature, and decomposes before boiling. All batches align with EINECS No: 209-150-3 and meet the requirements under HS Code 29157090.

FAQs of Magnesium Stearate:

Q: How is Magnesium Stearate produced?

A: Magnesium Stearate is synthesized through a chemical reaction between stearic acid and magnesium salts. This process yields a fine white powder that is widely used in various industries due to its effective lubricating and anti-adherent properties.Q: What are the main uses of Magnesium Stearate in the pharmaceutical and cosmetic industries?

A: In the pharmaceutical sector, Magnesium Stearate acts as a lubricant and glidant in tablet and capsule manufacturing, aiding in smooth processing and preventing ingredients from sticking to equipment. In cosmetics, it is used as a thickener and texture enhancer, improving product stability and feel.Q: When should Magnesium Stearate be used in industrial applications?

A: Magnesium Stearate should be added during manufacturing processes that require enhanced material flow or reduced friction, such as in plastics, coatings, or powder-based productions. Its stability and insolubility make it an excellent choice for such uses.Q: Where is Magnesium Stearate commonly sourced and supplied from?

A: Magnesium Stearate is globally manufactured and widely supplied by distributors, exporters, and manufacturers in industrially advanced regions, including India. Suppliers ensure compliance with international standards to meet diverse industrial and pharmaceutical demands.Q: What is the ideal storage condition for Magnesium Stearate?

A: Magnesium Stearate should be stored at room temperature in a dry, well-ventilated area to maintain its stability and prevent contamination. Proper storage helps preserve its purity and functional integrity.Q: How does Magnesium Stearate benefit product formulation?

A: Magnesium Stearate improves the flow properties of powders, reduces friction, aids in uniform product blending, and enhances the overall manufacturability of pharmaceutical and cosmetic products. These benefits make production processes more efficient and products more consistent.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free